MRV-S'' (mini)

Available models:

- AU042FNERA

- AU052FNERA

- AU042FPERA (AU04IFPERA)

- AU052FPERA (AU05IFPERA)

- AU062FPERA (AU06IFPERA)

- AU08NFKERA

- AU10NFKERA

- AU12NFKERA

ADVANCED TECHNOLOGY

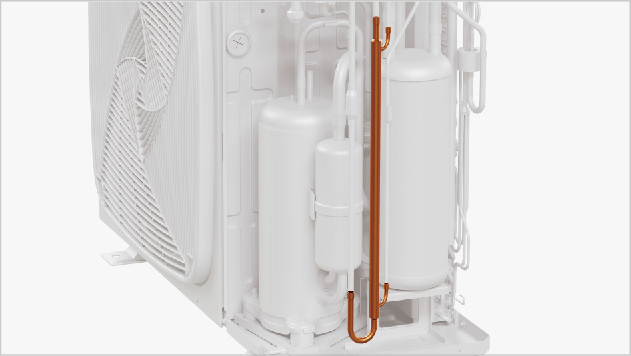

Leadership in technology(4-6HP)

- Two-stage supercooling cycle technology, increased unit efficiency by 9%. (Double fan)

- Maximizing 30°C undercooling, increase unit refrigerating capacity by 46%.

Increasing enthalpy bu replenish gas, realize the unit powerful heating capacity

Taking the heating cycle as an example, when environment tempetature is low, heat exchanged capability of outdoor unit is depressed. The amount of air returned by compressor is reduced, Increase the amount of refrigerant in the heating cycle of the indoor unit heat exchanger, Thereby achieving improved heating capacity.

High EER and COP(8/10/12HP)

The promotion of energy efficiency.

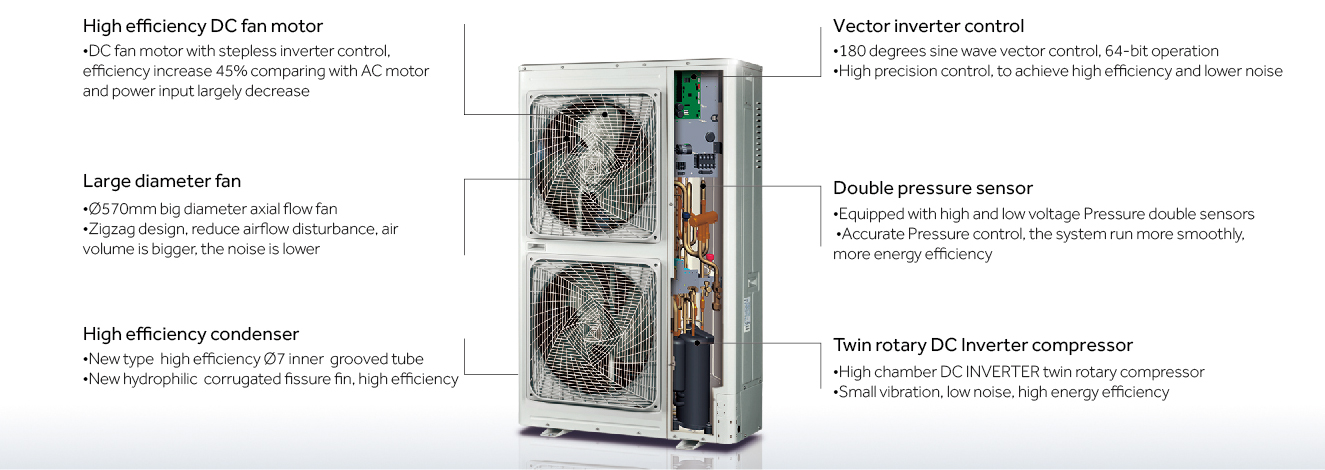

DC fan and fan motor

- DC inverter fan motor more higher efficiency in part load running

- 16-stage speed control; high efficiency running especially in low speed

- Efficiency increase 45% comparing with AC motor and power input largely decrease

- Big diameter fan

- 570mm big diameter fan, more big air flow and more higher efficiency(8/10/12HP)

Upgraded configuration, upgraded performance (8/10/12HP Side Discharge)

Bigger outdoor capacity, more flexible application.

Indoor units and outdoor units self-cleaning

Indoor units and outdoor units cleaning mode conversion with nonstop, make abundant use of ODU waste heat to IDU defrosting. At the same time, the IDU uses the waste heat of the ODU to defrost the heat exchanger, to dry the condensed water, effectively prevent mold breeding.

HIGH EFFICIENCY

High energy efficiency

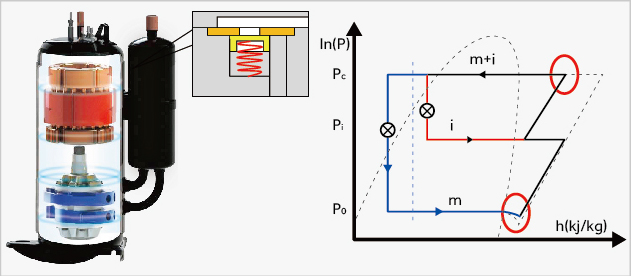

DC inverter compressor

Haier takes DC INV. compressor, 5% power input lower. (14kW)

DC fan motor and 550mm big fan

38% power input I ower and 8% airflow higher

Larger heat exchanger

Heat exchange area rise 10%

Charge Valve

Built-in charge valve enables safer and easier maintenance

Low standby power

New PCB programme, reduce 20% standby power consumption

Low noise level

Night Quiet Operation Function Noise can be reduced to 45dB(A).

New DC inverter twin rotary compressor

- Small torque change, good dynamic balance, the system runs stably, little vibration, low noise, high efficiency.

- More higher efficiency in part load running.

SUPER COMFORT

- New aerodynamics fan 550mm super big diameter aerospace helix fan. lowering sound level 3dB(A).

- Enlarged air inlet path and spiral air outlet path Air flow direction follows the grill direction.lowering sound level 2-4 dB(A).

- Automatic sound-lowering programme Night mode set by PCB, 8dB(A) low er.

Low noise operation

- DC INVERTER compressor, smooth operation, no need frequent start the com pressor, effectively reduce the noise outdoor.

- Vector inverter control, more precise control.

- DC fan motor, motor bracket used the non-resonance structure, ensure smooth running of the motor, reduce operating noise.

- Big diameter fan, design according to aviation quieter principle.

Easy installation

Compact Side Discharge Design, Big Capacity, Small Footprint / Small footprint, only 0.42m2, 43% floor area can be reduced.